If the Master Data Is Messy, AI Will Scale the Mess — Fast

My very first task after university while setting up an ERP system for a manufacturer? Master data cleansing. That was in the late 90s.

Last month, I walked into a client's plant — and found the exact same problem. Except now they were about to feed it into an AI planning tool.

I wrote down the 10 data fields every operations leader should audit before touching AI. And what "good enough" data quality actually looks like.

If you're planning an AI project in supply chain or production — read this first.

I know that's not what you want to hear because it is less appealing than playing around with AI, deep learning and other fancy stuff. Though after many years in business-driven (IT) applications, , it's the most vital lesson I keep watching companies learn the hard way.

Start fixing your bills of materials (BOMs). Start fixing your master data.

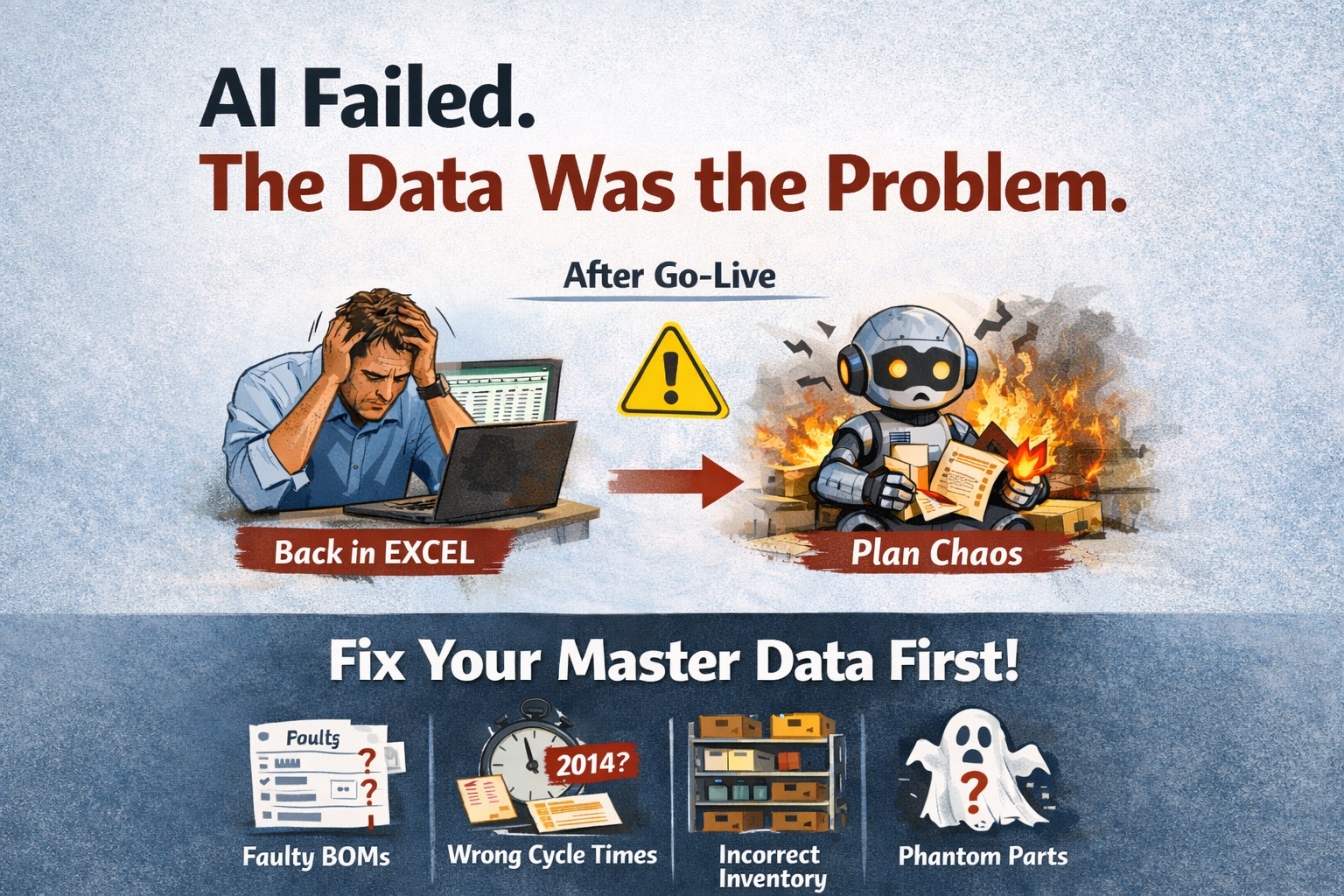

You've seen the demo.

The AI-powered planning dashboard looks incredible. Demand sensing. Automated scheduling. Real-time optimization. The vendor is confident. Your board is excited. The business case writes itself.

Then you go live.

And within two weeks, your planners are back in Excel. Firefighting. Overriding. Doing exactly what they did before—except now they're also babysitting an AI that keeps producing nonsensical plans.

What happened?

The algorithm was fine. Your data wasn't.

This Is Personal for Me

My very first job during university was setting up ERP system for manufacturing companies in the Basel region (Switzerland). And the first task I was given? Cleaning up master data, though they did not call it like this back then.

I remember staring at a routing file where the same operation had three different cycle times depending on who had entered it. Lead times that hadn't been updated since 2014. BOMs with phantom components nobody could explain.

That was over 25 years ago.

Today, I walk into client plants as a consultant—and the first thing I still do is check the master data. Not the dashboards. Not the KPIs. The master data.

It tells me everything I need to know about what's really going on.

The Uncomfortable Truth About AI in Planning

Here's what most AI vendors won't tell you:

AI doesn't fix bad data. It amplifies it.

A human planner sees a lead time of 0.5 days for a complex assembly and thinks, "That can't be right." They pick up the phone. They adjust.

An AI sees 0.5 days and schedules everything downstream accordingly. Across 200 product variants. In seconds. Before anyone notices.

Now multiply that by every wrong routing, every outdated calendar, every missing BOM level in your system.

That's not optimization. That's automated chaos.

The result? Planners lose trust in the tool within days. The AI project gets quietly shelved. Leadership blames "the technology." But the technology was never the problem.

The data was.

The Top 10 Planning Data Fields You Must Audit Before Any AI Project

Before you spend a single Euro, Dollar or Yen on AI-driven planning, audit these ten fields. They are the foundation everything else sits on.

1. Bills of Material (BOMs) Are they complete? Are phantom levels cleaned up? Do they reflect what's actually being built on the shop floor today—not what was built three years ago?

2. Routings / Work Plans Do your operation sequences match reality? Are work centers assigned correctly? One wrong routing means every scheduling decision downstream is wrong.

3. Cycle Times / Processing Times When were they last measured? Estimated times from 2018 are not planning parameters—they're fiction.

4. Setup Times Are they sequence-dependent? Are they captured at all? Missing setup times are one of the biggest hidden drivers of schedule deviation.

5. Lead Times (Production + Procurement) Are these maintained per material or just default values someone entered once? Blanket lead times are planning poison.

6. Production Calendars / Shift Models Does your system know which lines run two shifts, which run three, and which are down for maintenance every other Friday? If not, your capacity planning is fantasy.

7. Lot Sizes / Order Quantities Are minimum, maximum, and rounding values set correctly—or are they leftovers from a long-gone production setup?

8. Safety Stock Levels When was the last time these were reviewed? Static safety stocks in a dynamic environment create either excess inventory or stockouts. Usually both.

9. Scrap Rates / Yield Factors Are planned scrap rates close to actual scrap? A 2% planned rate on a process that actually scraps at 8% will systematically under-plan every order.

10. Material Status / Lifecycle Flags Are discontinued, blocked, or phased-out materials properly flagged? Nothing confuses an AI planner faster than planning demand for a material that no longer exists.

What "Good Enough" Looks Like: Minimum Viable Data Quality

Perfection is the enemy of progress. You don't need 100% data quality to start. But you do need minimum thresholds.

Here's what I recommend as a starting baseline:

Data Field Minimum Viable Threshold BOM accuracy ≥ 98% match to actual production Routing correctness ≥ 95% of operations verified in last 12 months Cycle times ≥ 90% measured (not estimated) within last 24 months Setup times Captured for ≥ 80% of operations with changeovers Lead times Reviewed and updated within last 12 months Calendars 100% aligned with actual shift schedules Lot sizes Reviewed within last 12 months Safety stocks Recalculated within last 6 months Scrap rates Within ±2 percentage points of actual Material status flags 100% flagged for discontinued/blocked items

If you're below these thresholds, you're not ready for AI-driven planning. Full stop.

But here's the good news: getting there is not a multi-year program. It's a focused sprint. And it is worth it, because the benefits of using AI-driven planning are tremendous, if the requirements are fulfilled.

How to Start: One Product Family, One Line, Expand From There

The biggest mistake I see companies make? Trying to clean up all master data across all plants at once.

Don't do that. It will take forever, cost too much, and die quietly in a spreadsheet.

Instead:

Pick one product family or one production line. Choose one that matters—high volume, high revenue, or high pain.

Audit the 10 fields above for that scope only. It takes 2–4 weeks, not 2 years.

Fix what you find. Involve the people on the shop floor. They know what's wrong. They've been working around it for years.

Measure the improvement. Track plan adherence, schedule stability, and firefighting hours before and after the cleanup.

Then expand. Take the process, the checklist, and the lessons learned to the next line. And the next.

By the time you're ready to bring in AI, your data foundation will actually support it. And your planners will trust the output—because the inputs finally make sense.

The Bottom Line

AI in production planning is powerful. But it's only as powerful as the data it's built on.

If your master data is a mess, AI won't save you. It will scale the mess faster than any human ever could.

The unsexy truth is that the companies winning with AI in supply chain aren't the ones with the fanciest algorithms. They're the ones that did the boring work first. They fixed the BOMs. They measured the cycle times. They cleaned up the calendars.

They earned the right to let AI plan.

I've made it my career to help companies do exactly that—starting with the data, not the dashboards.

If this resonates, I'd love to hear from you.

#SupplyChain #MasterData #AIinManufacturing #DataQuality #ProductionPlanning #S&OP #ManufacturingExcellence